A bit of theory

Noise is measured on a scale of decibels adjusted to the human ear, called decibels A (dBA). This scale is measured as a function of sound pressure and is based on a base-10 logarithmic scale. Decibels use the pascal (Pa) as the unit of pressure.

Without going directly into the formula, it is important to know that a doubling of energy represents a total increase of 3 dB. This is considered barely perceptible by humans. For example, two machines producing 50 dB individually produce 53 dB together, and not 100 dB. Since this is not a linear relationship, it is difficult to quantify a decibel increase without a metering device. In fact, a 10 dBA increase in noise is considered by humans to be twice as loud

Legal context

In Canada, the maximum allowable exposure level is consistent across all provinces. The limit for a continuous eight-hour exposure is 85 dBA.

Conventional protection

Personal protective equipment is the most common form of protection in industrial settings. When the noise is very intense, double protection may be required, such as wearing earmuffs over in-ear plugs. However, such protection can cause problems when communicating with colleagues.

So, the best protection is reducing noise at the source. This way, several methods can be considered, including insulated walls, partitions or enclosures. Each has its advantages and disadvantages, so the method must be assessed and adapted as much as possible to equipment handling.

The conventional method of reducing noise levels for a generator set is to add a complete acoustic enclosure around each generator. However, there are disadvantages to this approach:

- It is costly.

- It requires an additional ventilation system, often complex and voluminous, to cool the generators.

- Generator maintenance becomes more complex, as it requires several overhead cranes, or removable sound shelters.

- The building must be big enough to house the acoustic enclosure, increasing its space requirement.

Innovative means of protection: an example

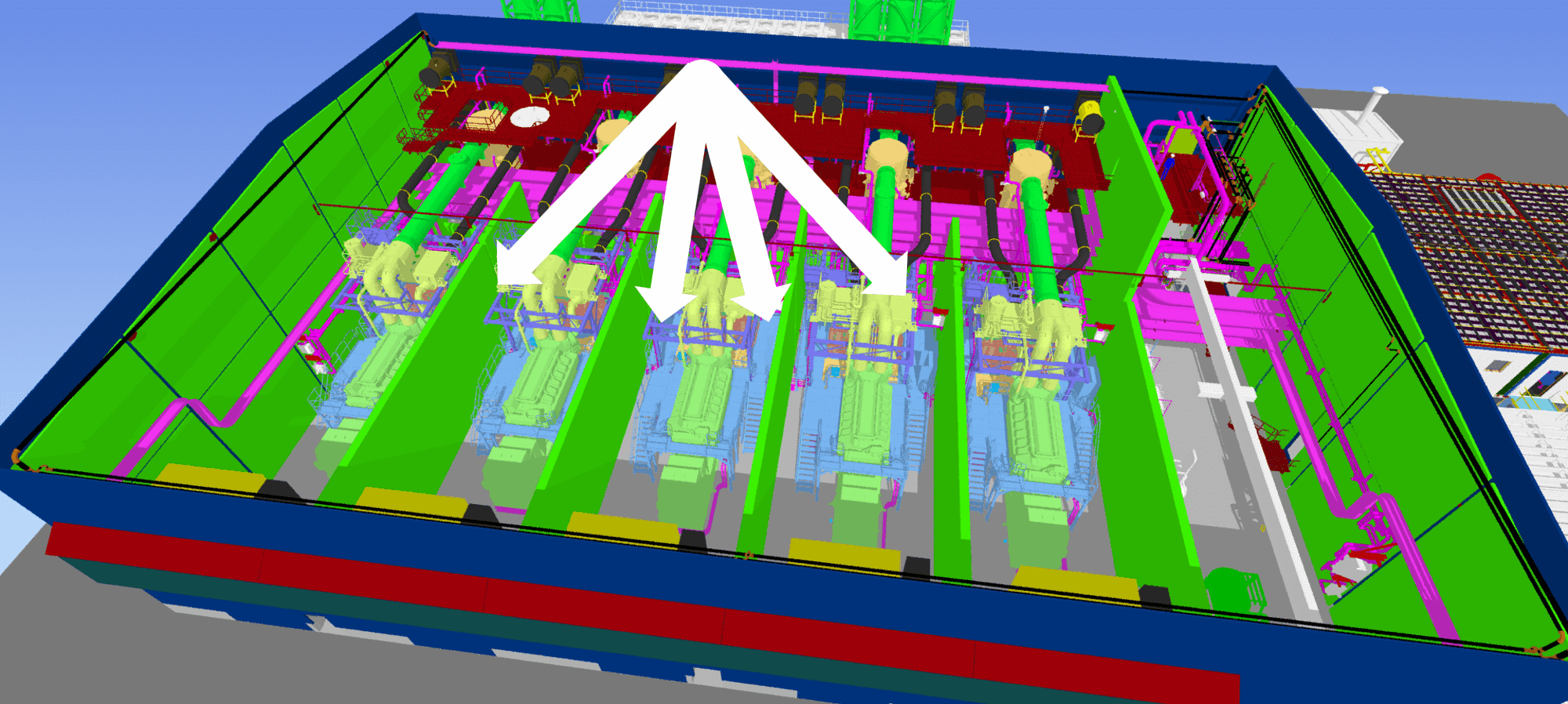

As part of a noise study performed on generator sets producing noise levels of up to 110 dBA, BBA experts proposed modifying the building design by adding acoustic walls in an innovative way.

To avoid workers having to wear double hearing protection, the entire ceiling was covered with acoustic panels, and acoustic walls were designed around the generator sets, yet did not reach the full height of the building, making it possible to use overhead cranes in the area and cool the generator sets. Additionally, the walls did not interfere with generator set maintenance.

Acoustic simulations helped optimize wall height to filter noise and ensure workers were only exposed to 94 dBA of continuous noise. This solution complied with the standard for noise exposure of 83 dBA for a consecutive 12-hour period simply by wearing earplugs.