Real challenges

New technology alone doesn’t guarantee a successful migration. During our work, we often have to migrate an HMI console and realize how complex it is to modify. In many cases, the original configuration was carried out by various work teams, who do not all adhere to the same standards when it comes to control logic and its graphical representation. Not to mention how difficult it is to find someone who knows the history behind this, and that there is often little documentation on the HMI configuration.

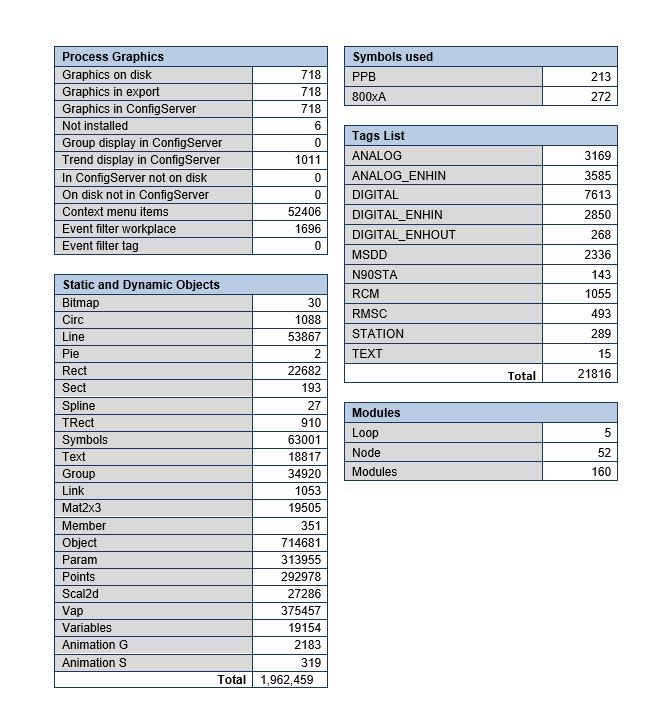

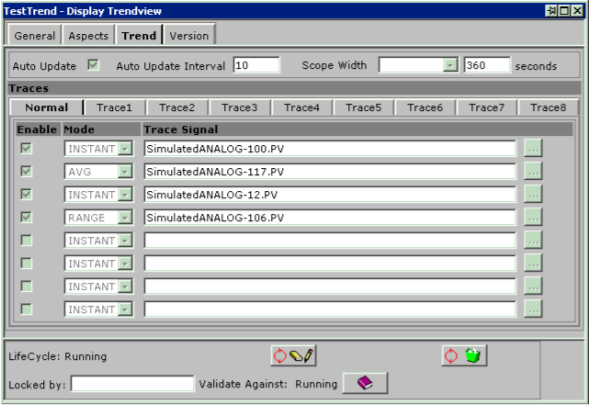

Migrating older HMIs to newer display technologies may prove to be even more cumbersome when the logic is embedded directly in the screen pages or when an excessively large quantity of graphic objects has been used, which could affect performance and dynamic behaviour. For example, overusing poorly defined tags in HMIs inevitably generates errors during manual conversion and makes the system hard to operate.

Even if it’s always possible to manually migrate a small number (100 or fewer) of HMIs, doing so on a larger scale (300 or more) usually leads to a range of problems during the project, including very long execution delays, budget overruns, unequal implementation of client standards, omissions and implementation errors. To reduce project costs, some manufacturers turn to an overseas group to have the bulk of these modifications done manually, with a different group carrying out the commissioning— thereby resulting in quality issues upon reception of the system and delays in transitioning to the new system. Lastly, these systems sometimes need to be completely reworked by the plant staff because of a lack in knowledge transfer among the various stakeholders.

A proven tool

To avoid these kinds of situations and facilitate the transition across HMI technologies, BBA has, over the past 25 years, developed a universal graphic converter (UGC) tool to manage all this complexity and perform a predictable migration of older technology to a newer one.